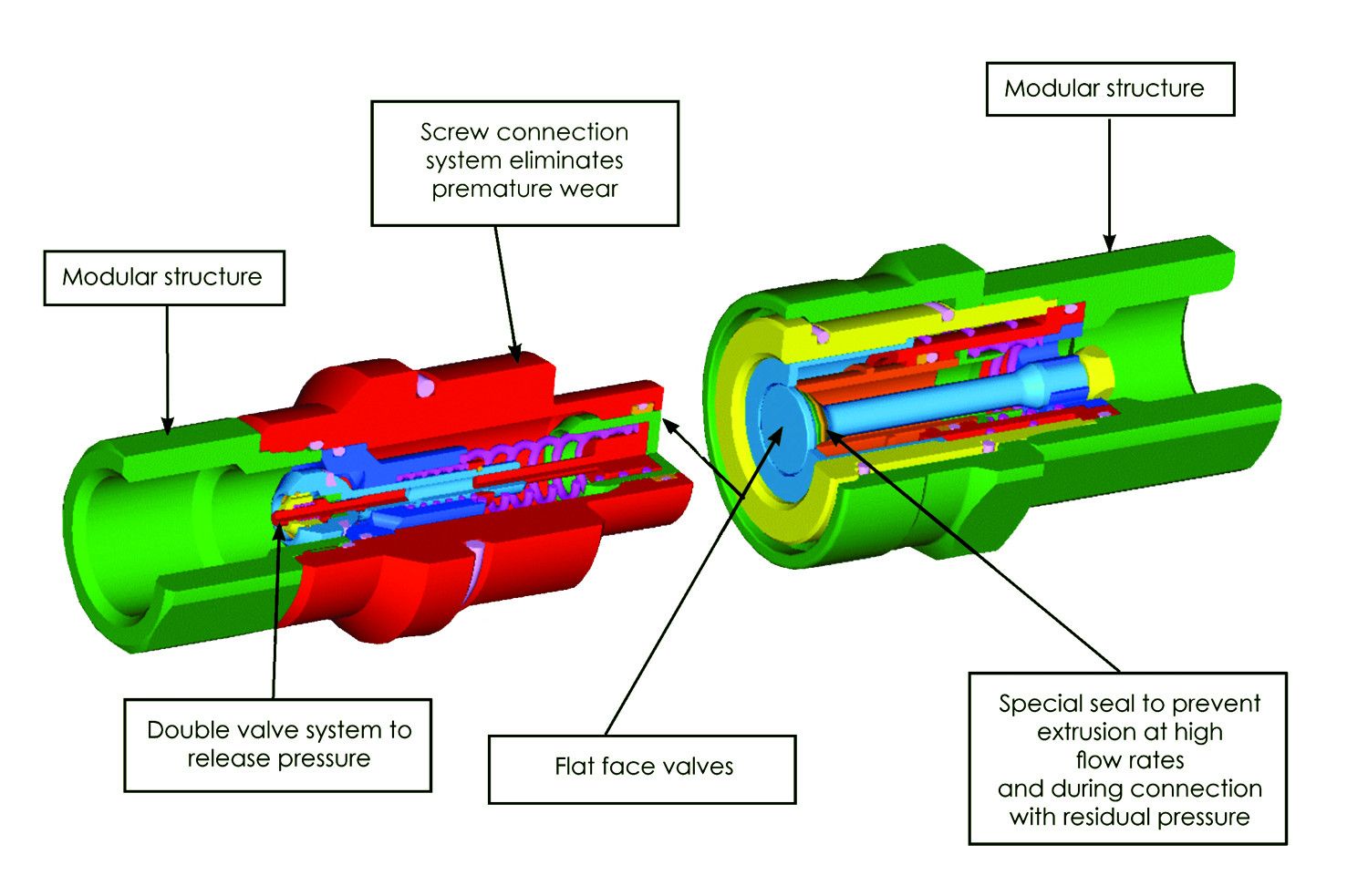

VEP Screwed - BSP Coupling

VEP High Pressure Screwed Hydraulic Couplings

- German made Manuli couplings

- Screw coupling with quick connection system

- Working pressure 35MPa

- Triple valve system that guarantees connection under pressure safely

- Interchangeable according to Manuli Q.Safe specifications

- Sealing system with flat valve

- Polyurethane seals

- Compact design

- Wide range of termination ends

MATERIAL

Couplings in steel with some stressed area hardened, carbonitrided valve, springs in C98 steel, seals in polyurethane and NBR, back-up ring PTFE

WORKING TEMPERATURE

-22ºF up to +230ºF (-30ºC up to +110ºC)

SAFETY FACTOR

4:1 for dynamic pressures

IMPULSE PRESSURES

1,000,000 cycles at 120% of rated one (freq. 1Hz) in connected and disconnected conditions

TEST SPECIFICATIONS

ISO 18869

HOW TO USE

- Before connecting, clean the flat mating surface of coupling to avoid inclusion of contamination into the circuit

- To connect pull forward the connection sleeve of the female coupling. Align the female and male coupling holding forward the connection sleeve and thread together turning the sleeve. Keep couplers aligned during connection process. Do not push to connect couplings. The screwing of the threads should be done by hand without the use of tools for the first part of the connection. The use of tools for the second part of connection can be necessary if there is high residual pressure in the circuit. Screw the connection sleeve of the female until metal surface contact with the male coupling is complete. Tighten the sleeve to the base of the male using the tightening torque spec. as indicated in the table below.

- To uncouple turn sleeve from contact position using a wrench, then uncrew making sure the couplings stay aligned throuh the entire process.